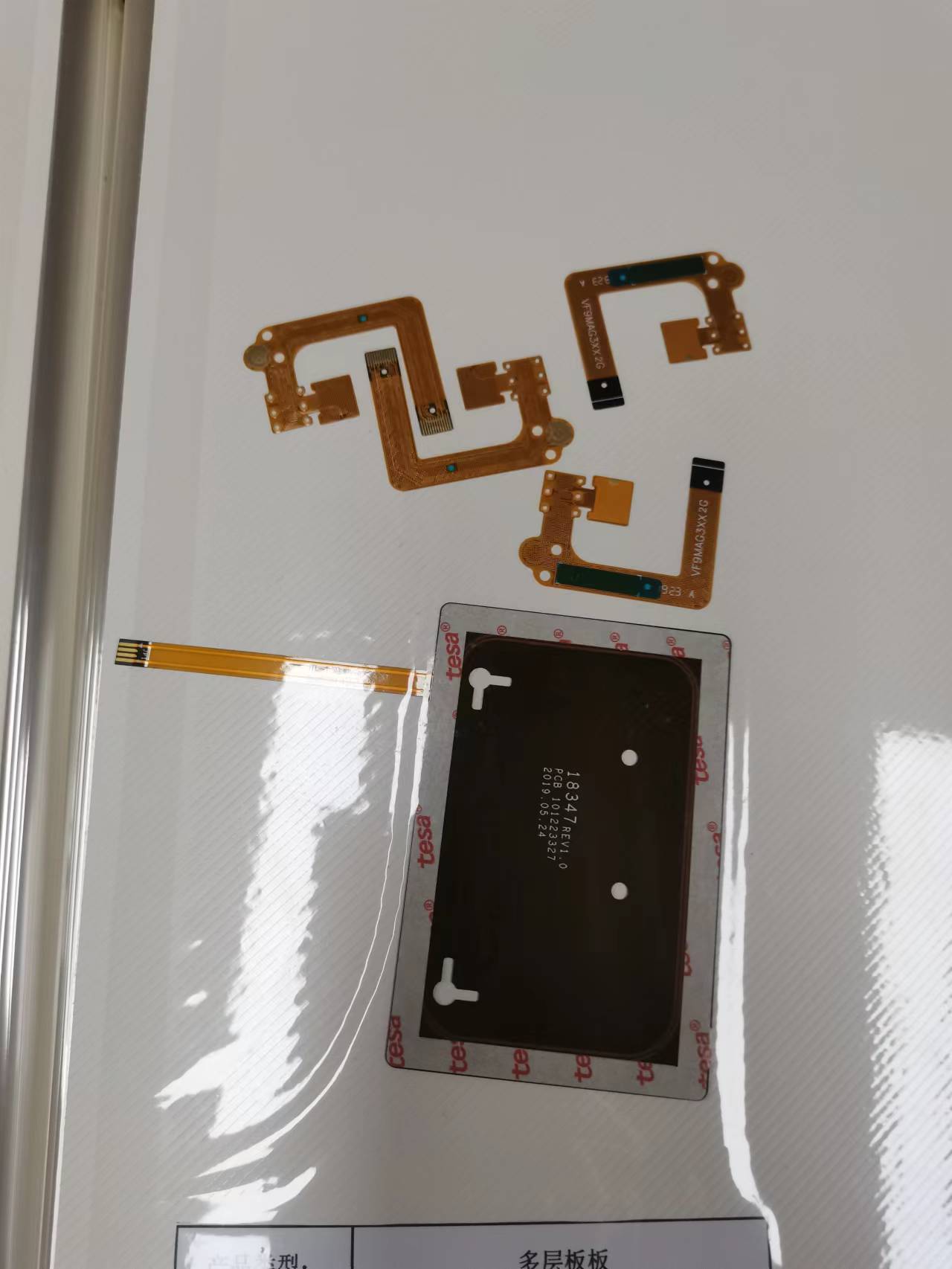

FPC production process

Folding Prenatal Pretreatment

To make a good quality FPC board, there must be a complete and reasonable production process. From pre-production pre-processing to final shipment, every procedure must be strictly implemented. In the production process, in order to prevent too many open and short circuits and cause too low yield or reduce drilling, calendering, cutting and other process problems caused by scrapping and replenishing FPC boards, and evaluate how to select materials to achieve customer use The best effect of the flexible circuit board. Prenatal pretreatment is particularly important.

There are three aspects of prenatal pretreatment that need to be dealt with, and all three aspects are completed by engineers. The first is the FPC board engineering evaluation, mainly to evaluate whether the customer’s FPC board can be produced, whether the company’s production capacity can meet the customer’s board manufacturing requirements and unit cost; if the engineering evaluation is passed, the next step is to prepare materials immediately to meet all production links. Finally, the engineer processes the engineering documents such as the customer’s CAD structure diagram, gerber circuit data, etc. to suit the production environment and production specifications of the production equipment, and then releases the production drawings and MI (engineering process card) and other materials to the The production department, document control, procurement and other departments enter the regular production process.

Folding 1 double panel process

Material cutting → drilling → PTH → electroplating → pretreatment → dry film sticking → alignment → exposure → development → pattern plating → film release → pretreatment → dry film sticking → alignment exposure → development → etching → film release → surface treatment → Applying cover film → Pressing → Curing → Immersion Nickel Gold → Character Printing → Cutting → Electrical Testing → Punching → Final Inspection → Packaging → Shipping

Folding 2 single panel process

Cutting material → drilling → sticking dry film → alignment → exposure → developing → etching → stripping → surface treatment → covering film → pressing → curing → surface treatment → immersion nickel gold → character printing → shearing → electrical measurement → punching Cutting → Final Inspection → Packing → Shipping

Post time: Jul-15-2022