Big Discount Transparent Pcb - FPC(FlexiblePrintedCircuit, FPC) – Xinhui

Big Discount Transparent Pcb - FPC(FlexiblePrintedCircuit, FPC) – Xinhui

Big Discount Transparent Pcb - FPC(FlexiblePrintedCircuit, FPC) – Xinhui Detail:

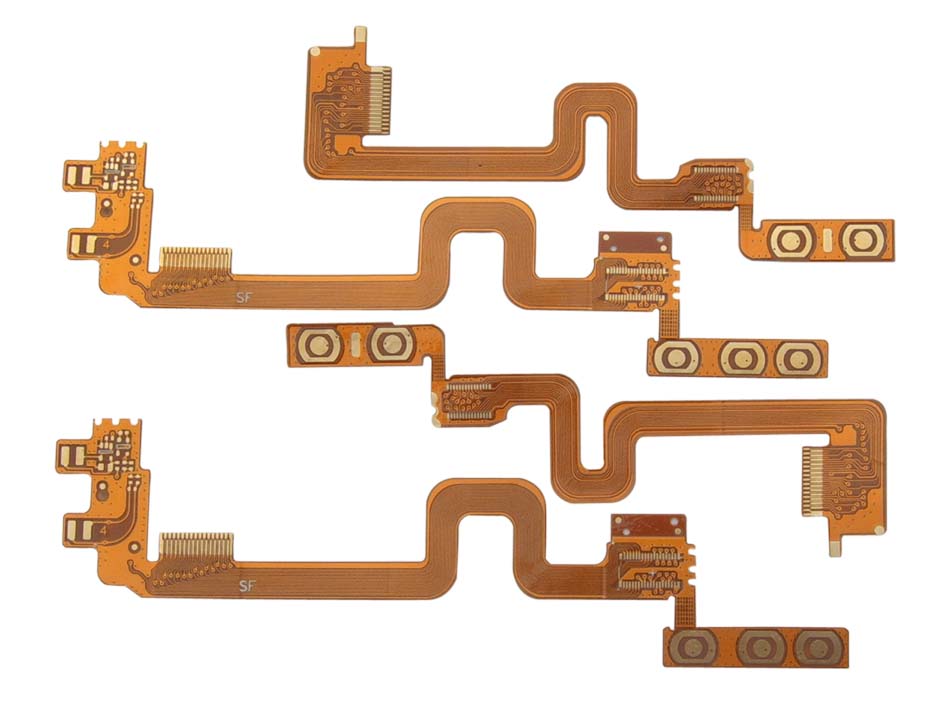

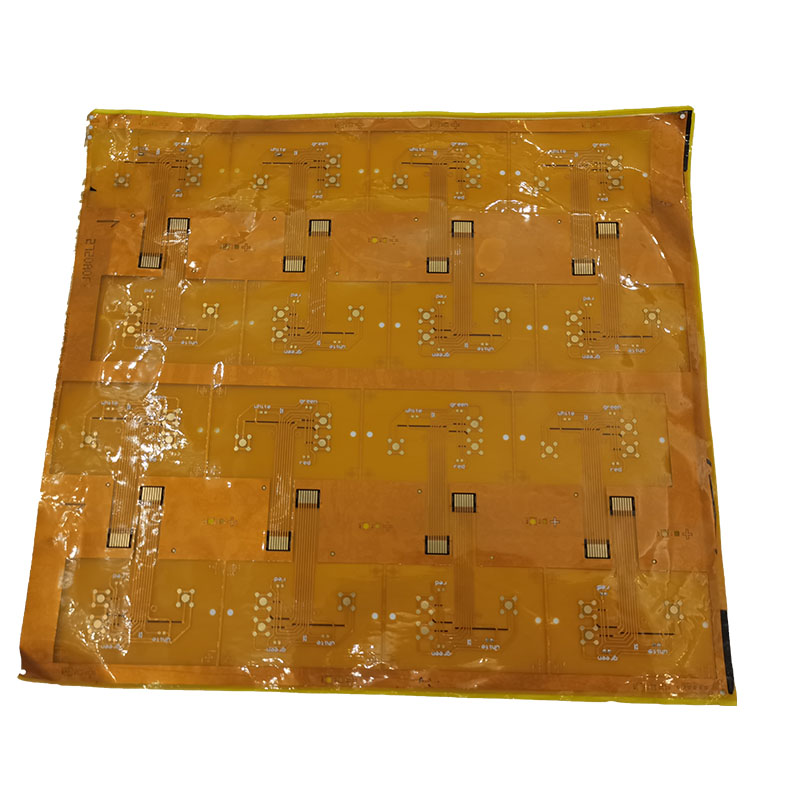

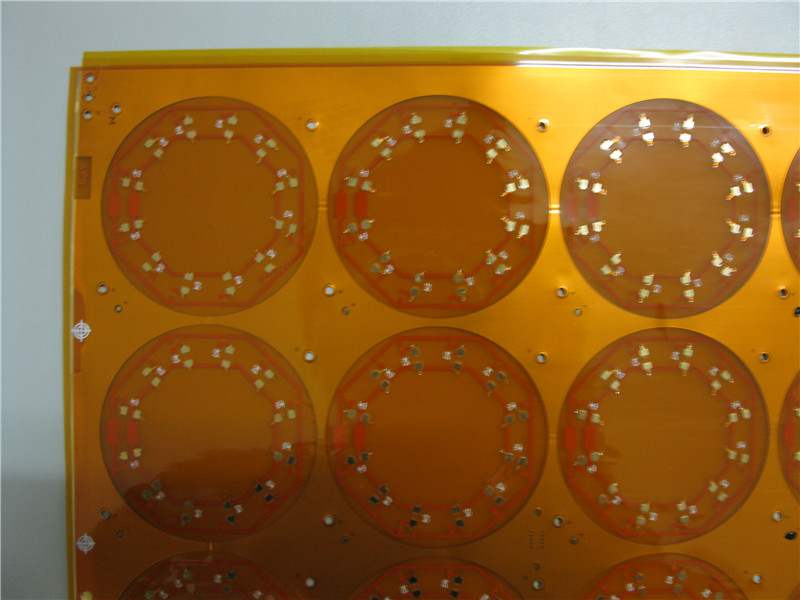

FPC product description

Flexible circuit (FPC) is a technology developed by the United States for the development of space rocket technology in the 1970s. It is made of polyester film or polyimide as a substrate with high reliability and excellent flexibility. By embedding a circuit design on a thin and light plastic sheet that can be bent, a large number of precision components are stacked in a narrow and limited space to form a bendable flexible circuit. This kind of circuit can be bent at will, folded, light weight, small size, good heat dissipation, easy installation, and breaks through the traditional interconnection technology. In the structure of the flexible circuit, the materials are insulating film, conductor and adhesive.

Basic structure

Copper Film

Copper foil: basically divided into electrolytic copper and rolled copper. The common thickness is 1oz 1/2oz and 1/3 oz

Substrate film: There are two common thicknesses: 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Cover Film

Cover film protection film: for surface insulation. Common thicknesses are 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing; easy to work.

Stiffener Film (PI Stiffener Film)

Reinforcement board: Reinforce the mechanical strength of FPC, which is convenient for surface mounting operations. The common thickness is 3mil to 9mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing.

EMI: Electromagnetic shielding film to protect the circuit inside the circuit board from outside interference (strong electromagnetic area or susceptible to interference area).

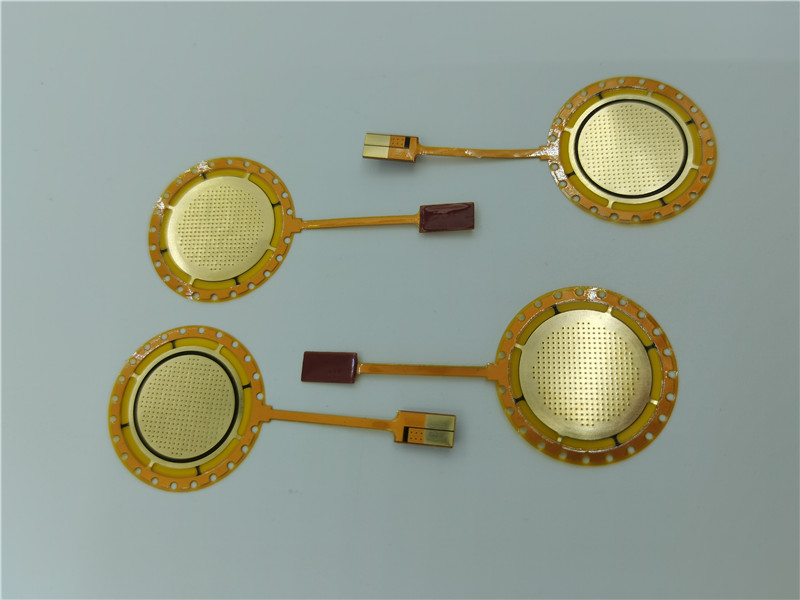

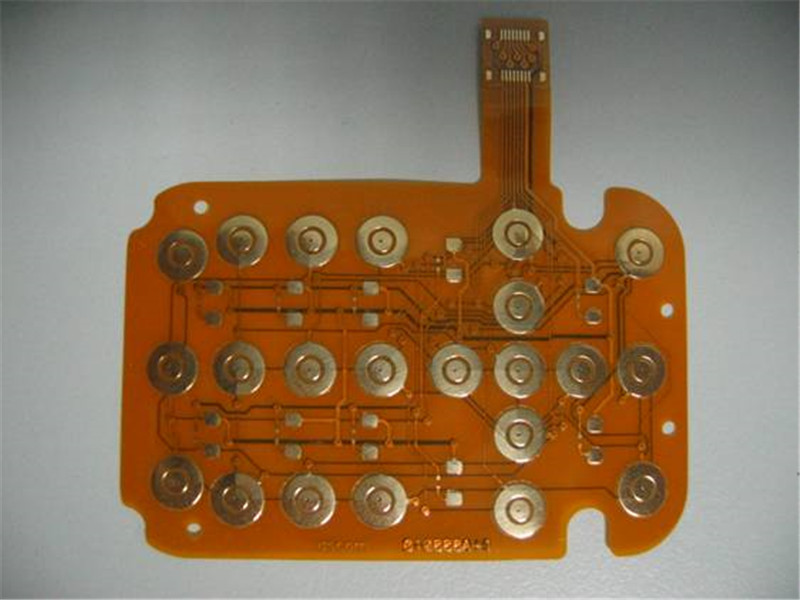

Product Show

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency revenue team values customers' wants and company communication for Big Discount Transparent Pcb - FPC(FlexiblePrintedCircuit, FPC) – Xinhui , The product will supply to all over the world, such as: Lahore, Washington, Algeria, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.