Factory source China Professional OEM Rigid Flex PCB Manufacturer Flexible Printed Circuit Manufacturer PCB FPC

Factory source China Professional OEM Rigid Flex PCB Manufacturer Flexible Printed Circuit Manufacturer PCB FPC

Factory source China Professional OEM Rigid Flex PCB Manufacturer Flexible Printed Circuit Manufacturer PCB FPC,

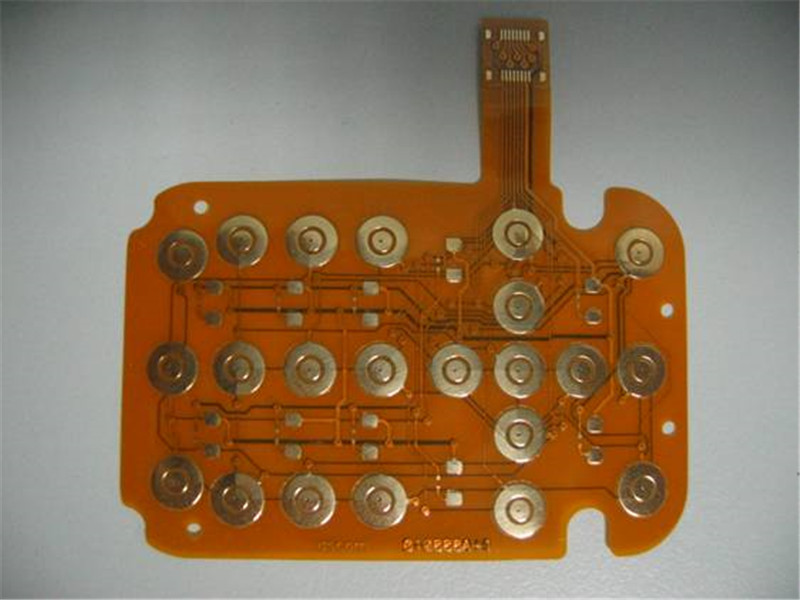

assembly FPC, button panel, four-layer FPC/PCB, membrane panel, membrane sticker, membrane switch, precision FPC, sticker,

FPC product description

Flexible circuit (FPC) is a technology developed by the United States for the development of space rocket technology in the 1970s. It is made of polyester film or polyimide as a substrate with high reliability and excellent flexibility. By embedding a circuit design on a thin and light plastic sheet that can be bent, a large number of precision components are stacked in a narrow and limited space to form a bendable flexible circuit. This kind of circuit can be bent at will, folded, light weight, small size, good heat dissipation, easy installation, and breaks through the traditional interconnection technology. In the structure of the flexible circuit, the materials are insulating film, conductor and adhesive.

Basic structure

Copper Film

Copper foil: basically divided into electrolytic copper and rolled copper. The common thickness is 1oz 1/2oz and 1/3 oz

Substrate film: There are two common thicknesses: 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Cover Film

Cover film protection film: for surface insulation. Common thicknesses are 1mil and 1/2mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing; easy to work.

Stiffener Film (PI Stiffener Film)

Reinforcement board: Reinforce the mechanical strength of FPC, which is convenient for surface mounting operations. The common thickness is 3mil to 9mil.

Glue (adhesive): The thickness is determined according to customer requirements.

Release paper: avoid the adhesive sticking to foreign matter before pressing.

EMI: Electromagnetic shielding film to protect the circuit inside the circuit board from outside interference (strong electromagnetic area or susceptible to interference area).

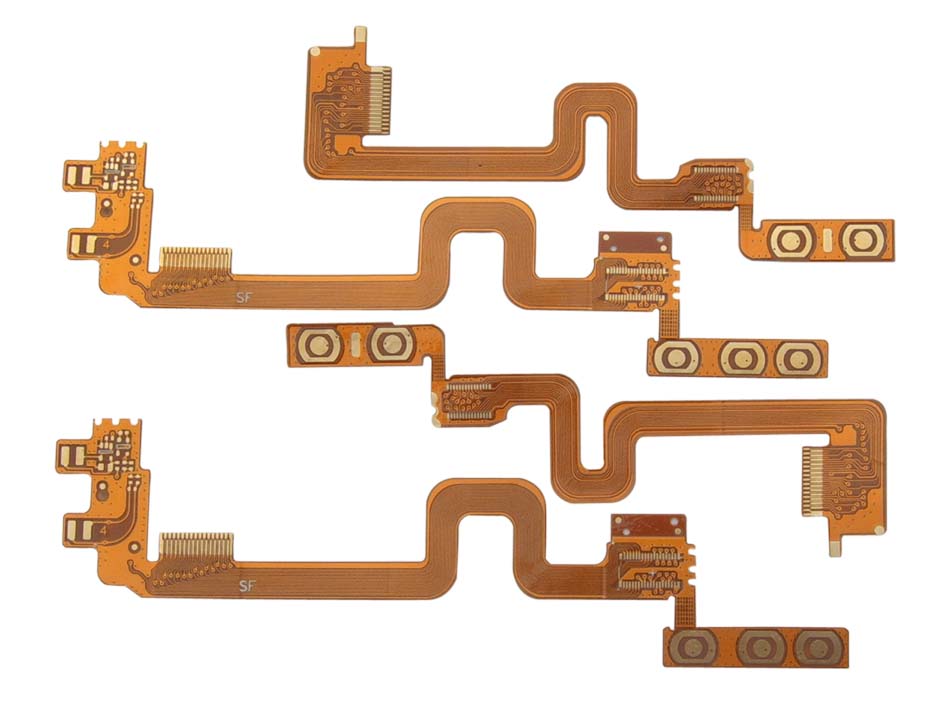

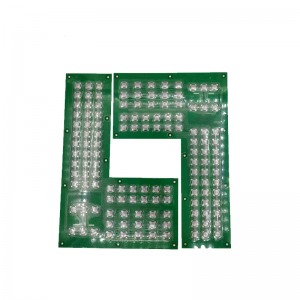

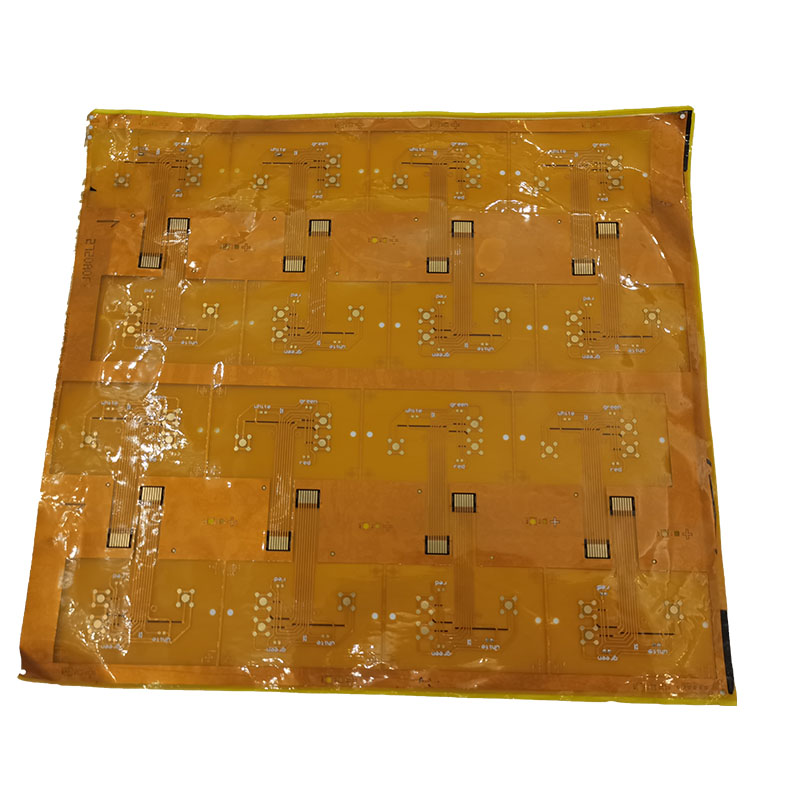

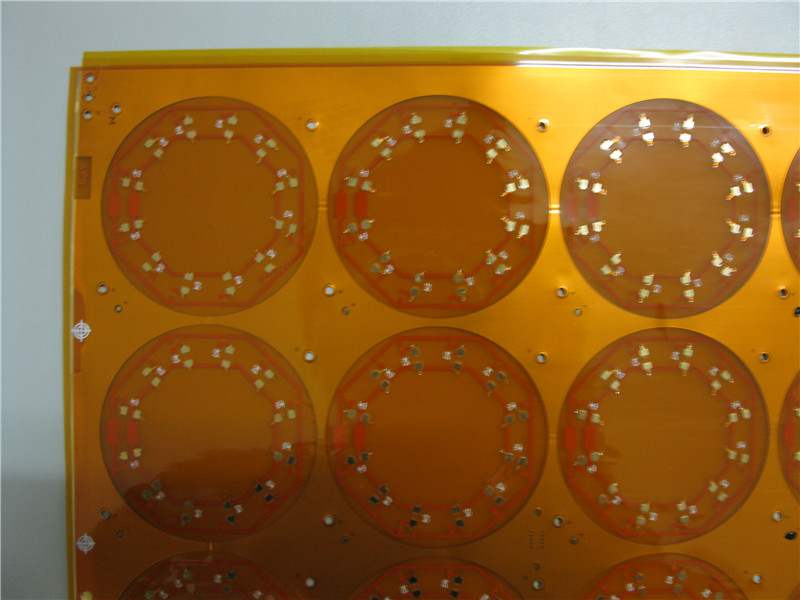

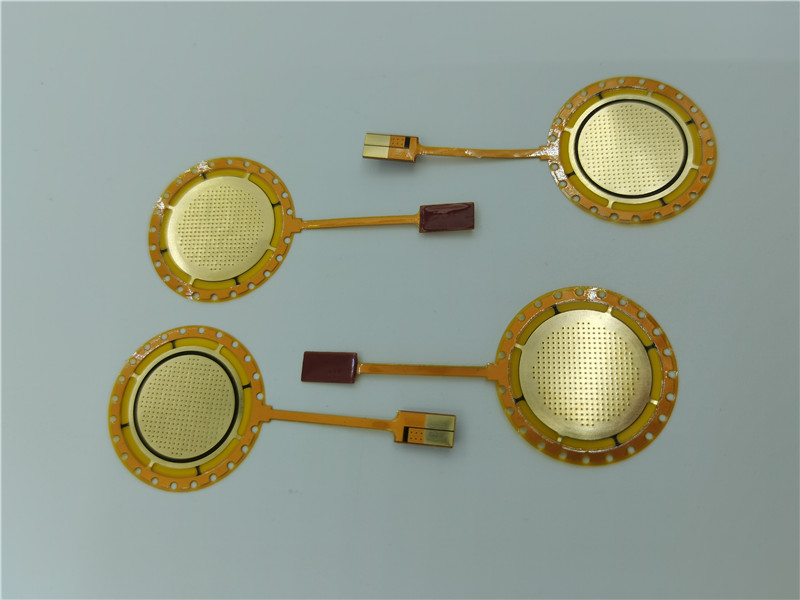

Product Show

Explanation of terms related to FPC

1. Access Hole exposed hole (through exposed hole, exposed bottom hole)

It often refers to the protective layer Coverlay on the surface of the soft board (the exposed hole must be punched out first), which is used as a solder mask to be attached to the surface of the soft board. However, it is necessary to deliberately expose the wall of the ring hole or the square welding pad required for welding to facilitate the welding of the parts. The so-called “Access Hole” in the original text refers to the surface layer with exposed holes, allowing the outside world to “approach” the solder joints on the board under the surface protection layer. Some multilayer boards also have such exposed holes.

FPC soft board impedance control circuit is also called impedance bar. When the current that needs to pass through the circuit is greater than the maximum value that the circuit can withstand, it is necessary to use impedance to control the excess current. This is the principle of impedance control. So how to control the value of the impedance line? Every aspect will affect the resistance of the impedance circuit:

1. Different substrates lead to different impedance values

The difference in the substrate material has a great impact on the soft board. The resistance value of each material is different, and the resistance value of each part of the same material will not be exactly the same, just as there are no two same leaves in the world. Kind of truth. The impedance line on the impedance board generally uses a substrate with good material stability. If the material with poor stability is used, the resistance value of the material will change greatly. Once the impedance value exceeds the required impedance value, the impedance line cannot be used. Control lines.

2. Different material thicknesses cause impedance changes

There are many similarities between this reason and the above material reason.

3. Line width spacing

The difference in line width and spacing between impedance lines will cause the resistance value to change. The impedance line is used as a resistor, so the width of the line is the size of the resistance value. What is the relationship between the absorption of the line spacing, the current between the lines will generate a magnetic field, and the magnetic field can also generate current (generator principle, which is why shielding). At this time, the current will change, which indirectly causes the impedance control data to be incorrect. precise.

4. Etching tolerances will cause impedance changes

Etching is a kind of corrosion to the circuit, which will affect the thickness and width of the circuit, so that we can return to the content mentioned above. Etching can only be kept within a range, and there are still deviations. These deviations are the reasons for the change in resistance.

5. Tolerance of electroplating copper

The impact of this depends on the process flow. In some processes, since the plating is before the time, it will not affect the impedance at this time. However, most of the fpc soft boards have been etched during electroplating. At this time, copper will also be attached to the impedance line, which will cause the resistance of the impedance line to change.