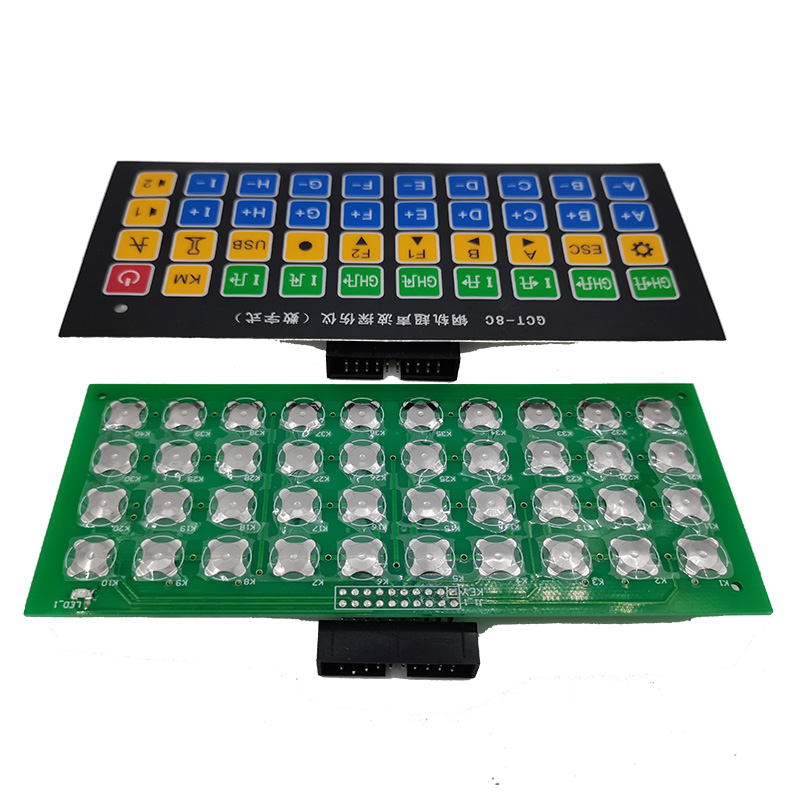

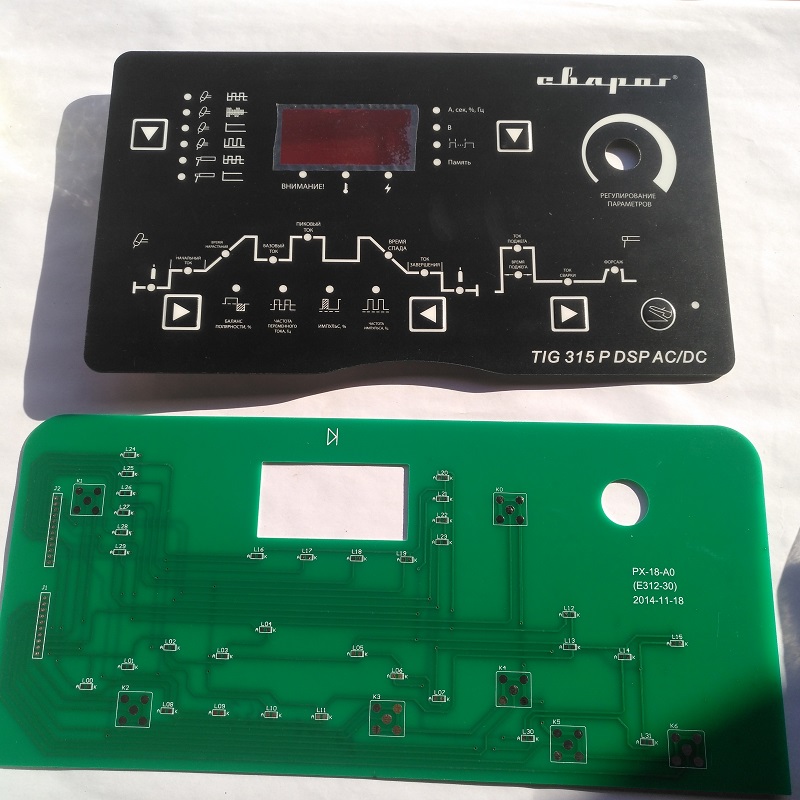

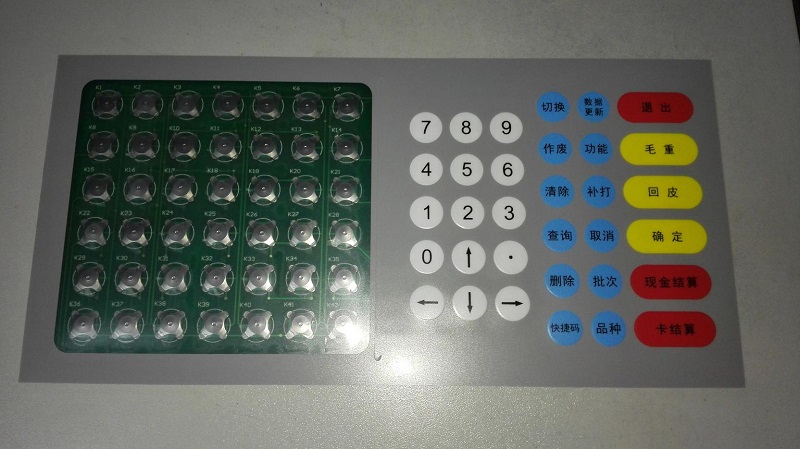

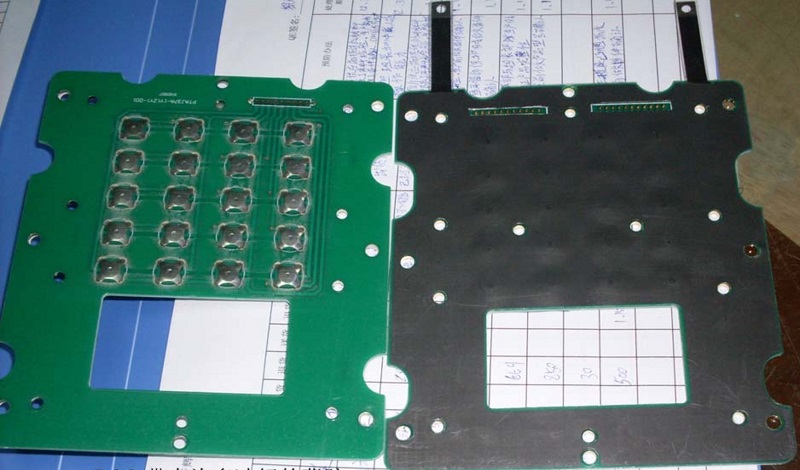

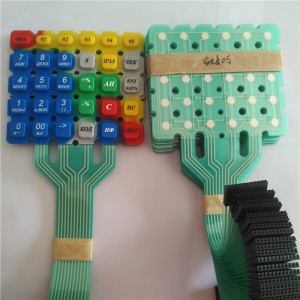

PCB keyboard(Portable electronic keyboard circuit)

PCB keyboard(Portable electronic keyboard circuit)

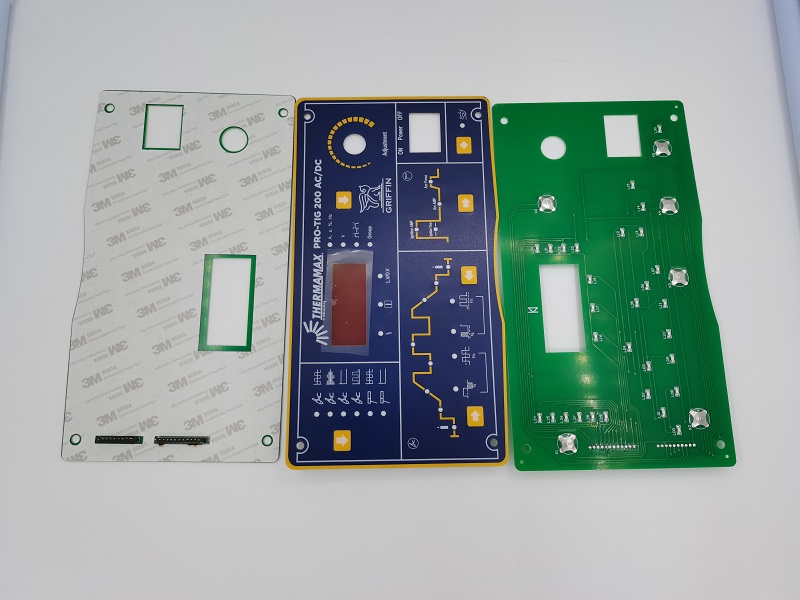

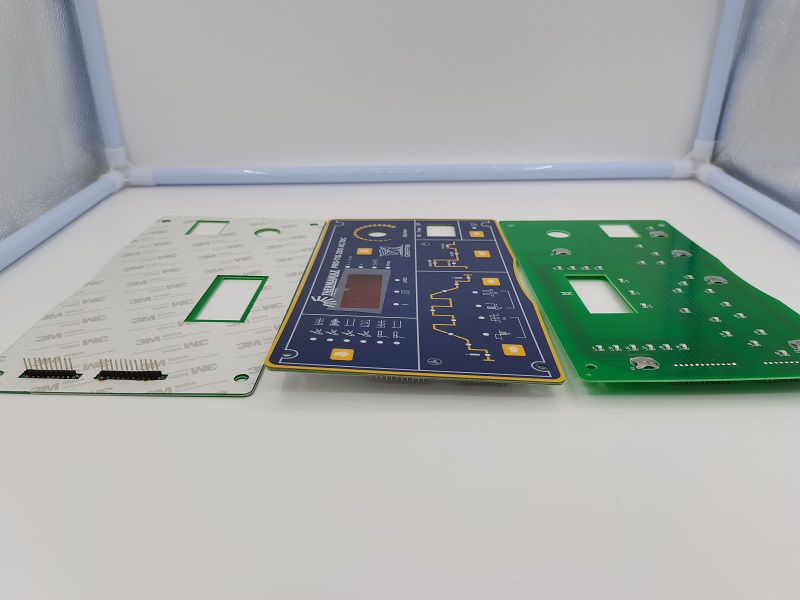

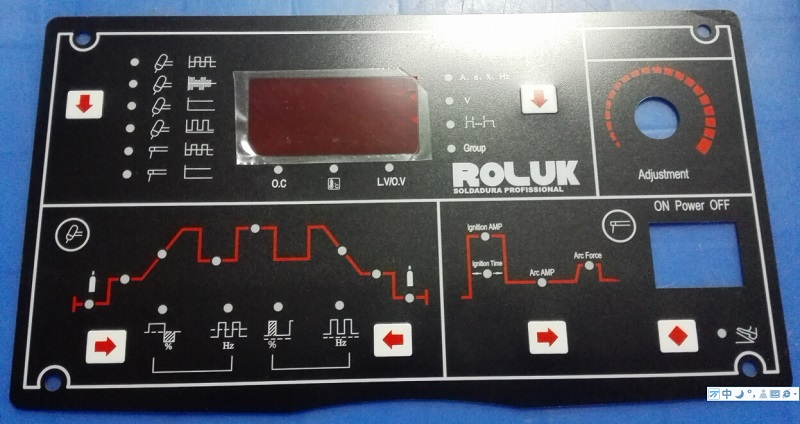

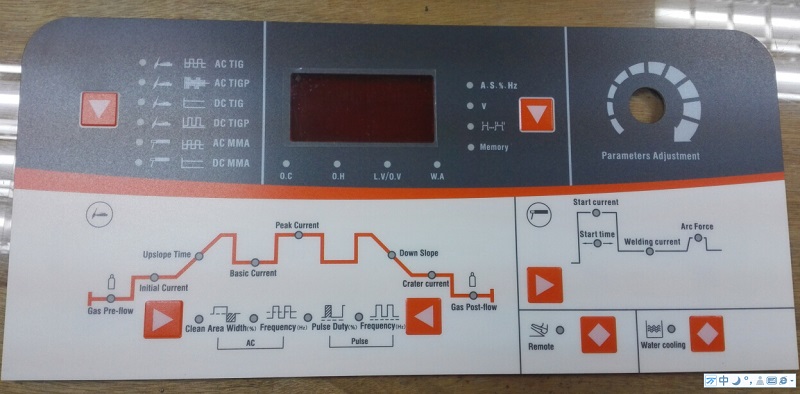

PCB membrane switch

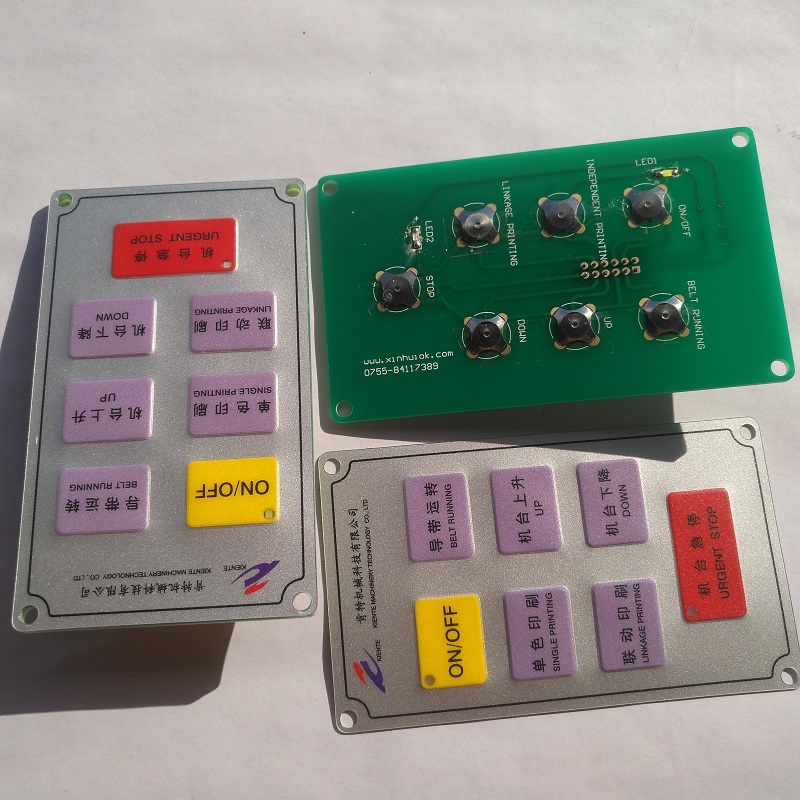

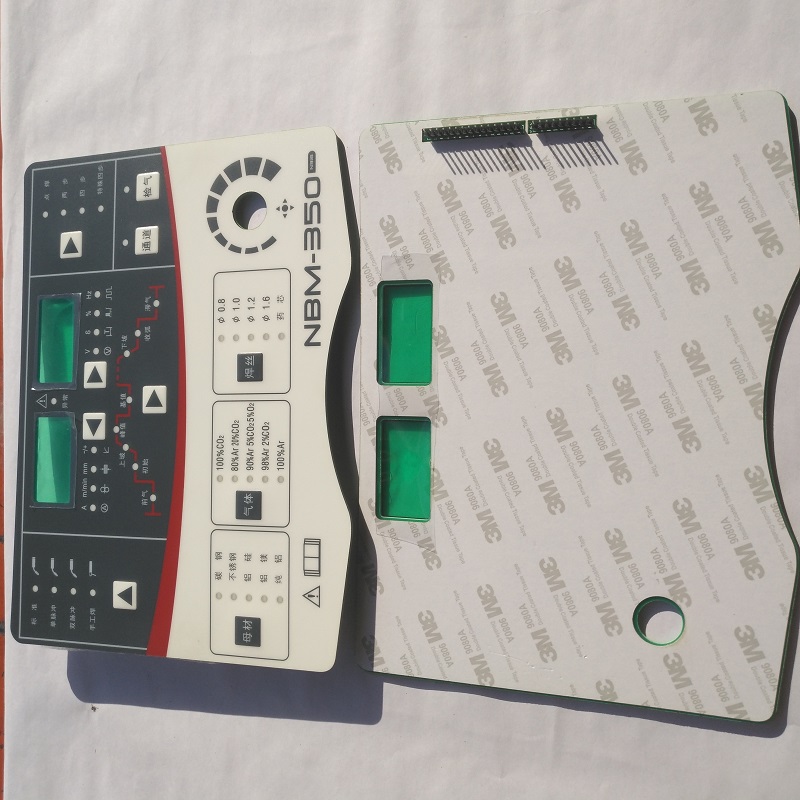

PCB membrane switch means that the pattern and circuit of the switch are made on the common printed circuit copper clad board.

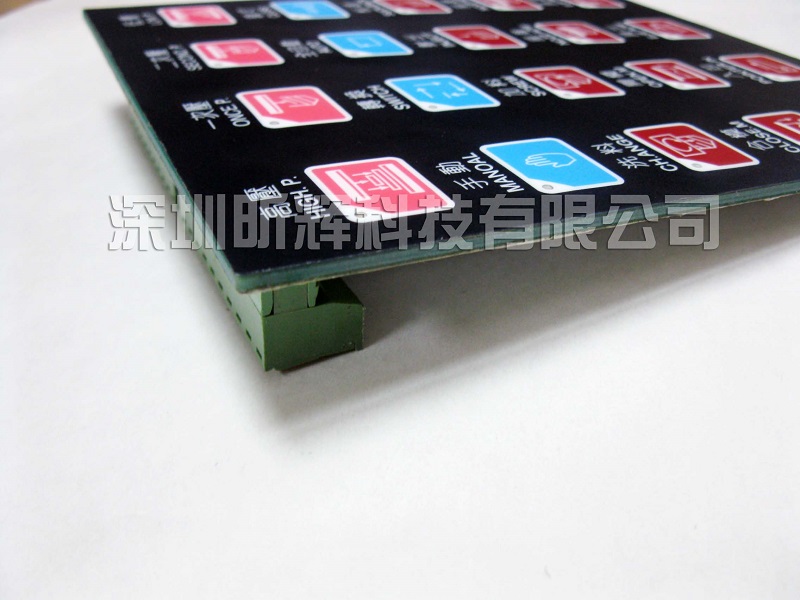

The characteristic of PCB membrane switch is that the material is easy to use, the process is stable, the resistance is low, and some components in the circuit can be directly welded on the back of the PCB. In the case of a small area, the hard liner layer can be omitted. PCB can be made with a thickness of 0.5mm-3.0mm.

PCB membrane switches generally use metal guides as conductive labyrinth contacts, so they have a better feel. The disadvantage is that it is not as convenient as the flexible membrane switch to install and connect in the whole machine, and it is often necessary to weld the connector and lead the lead through the flat cable. In addition to the buzzer signal and LED indication, the information feedback of the rigid membrane switch can generally use metal handle shrapnel.

Product related words: membrane switch, membrane key, membrane keyboard, FPC keyboard, PCB keyboard, electrical key membrane,

Toy membrane switch, capacitive touch switch, membrane control switch, medical circuit electrode sheet, waterproof membrane switch,

LGF luminous membrane switch, LED membrane keyboard, keyboard line switch, waterproof keyboard, membrane keyboard, ultra-thin switch button. Controller membrane switch

Related Parameters

| Membrane switch parametersameters | ||

| Electronic properties | Working voltage:≤50V(DC) | Working current:≤100mA |

| Contact resistance:0.5~10Ω | Insulation resistance:≥100MΩ(100V/DC) | |

| Substrate pressure resistance:2kV(DC) | Rebound time:≤6ms | |

| Loop resistance: 50 Ω, 150 Ω, 350 Ω, or determined according to the user's needs. | Insulation ink withstand voltage:100V/DC | |

| mechanical propertiesti | Reliability service life:>One million times | Closure displacement: 0.1 ~ 0.4mm (tactile type) 0.4 ~ 1.0mm (tactile type) |

| Working force: 15 ~ 750g | Migration of conductive silver paste: at 55 ℃, temperature 90%, after 56 hours, it is 10m Ω / 50VDC between two wires | |

| There is no oxidation and impurity on the silver paste line | The line width of silver paste is greater than or equal to 0.3mm, the minimum interval is 0.3mm, the rough edge of line is less than 1 / 3, and the line gap is less than 1 / 4 | |

| Pin spacing standard 2.54 2.50 1.27 1.25mm | The bending resistance of outgoing line is 80 times with d = 10 mm steel rod. | |

| Environmental parametersme | Operating temperature:-20℃~+70℃ | Storage temperature: - 40 ℃ ~ + 85 ℃, 95% ± 5% |

| Atmospheric pressure:86~106KPa | ||

| Printing index index | The printing size deviation is ± 0.10 mm, the outline side line is not clear, and the weaving error is ± 0.1 mm | The chromatic deviation is ± 0.11mm/100mm, and the silver paste line is completely covered by the insulating ink |

| No ink scattered, no incomplete handwriting | The color difference is not more than two levels | |

| There shall be no crease or paint peeling | The transparent window shall be transparent and clean, with uniform color, without scratches, pinholes and impurities. | |